City of Crane

- treatment

- Crane, Texas

Project Scope

1.3 MGD

Construction Type

Improvement

Project Delivery Method

Design-Bid-Build

Project Components

Hydraulic design, piping, architectural and structural, arsenic treatment process

In 2006, the Texas Commission on Environmental Quality (TCEQ) began enforcing a new arsenic maximum contaminant level (MCL) of 0.01 mg/L. Crane, Texas, had historical arsenic levels just above the MCL at 0.013 mg/L. The city entered many compliance plans with TCEQ but eventually came under direct enforcement from the Environmental Protection Agency. The City of Crane contacted Parkhill to find a treatment solution for their arsenic problem.

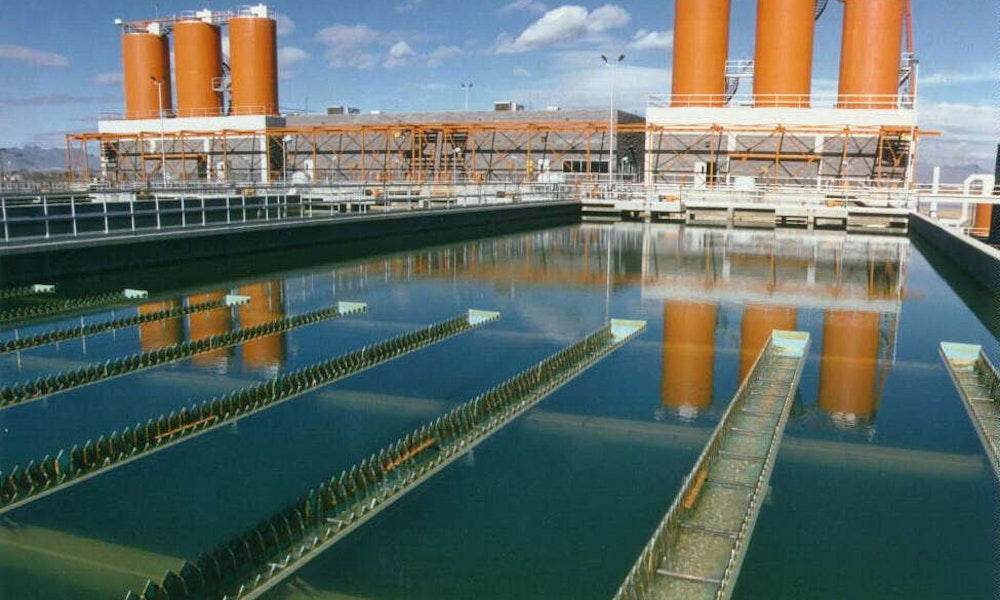

In order to develop a successful water treatment solution for Crane, Parkhill examined the existing water conditions of the city before beginning the plant design. Historically, the City of Crane has had a stable water use flow. The city pumps water from over 50 wells through 3 pump stations before distributing to the customers. The results indicated an average water flow of approximately 1 million gallons per day (MGD) and a peak of 2 MGD of water usage. Water is precious in Crane, because of the high cost to bring it into the city. As a result, Parkhill saw a need to minimize the rejection or backwash flow, and used these flow parameters to design the arsenic water treatment plant.

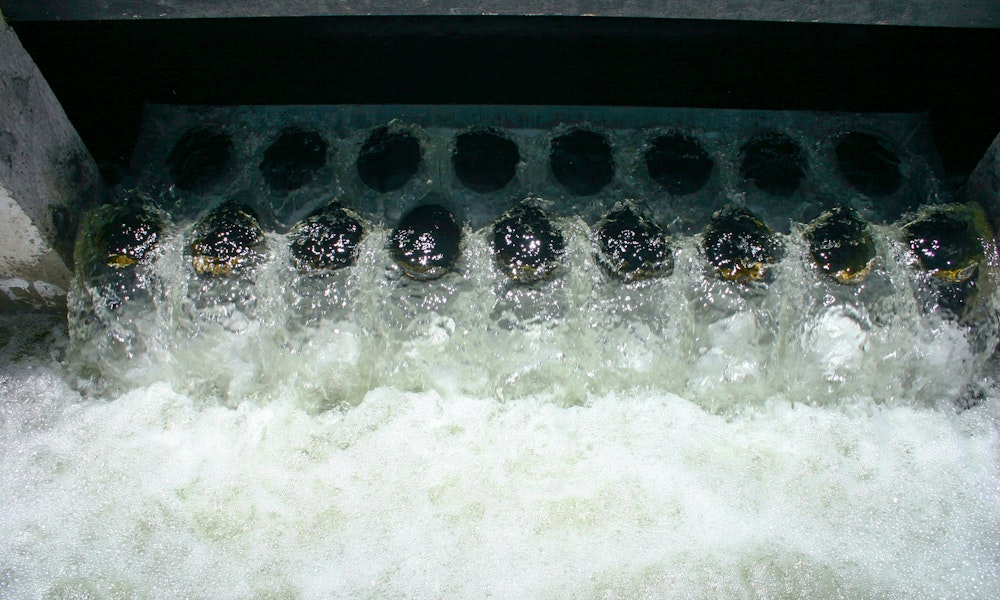

Parkhill presented the city with two options to remove arsenic from their water. The City of Crane chose to implement an iron-adsorption technology that would run water through two large pressure filters containing the adsorption media. The adsorption technology was able to treat the arsenic down to lower levels allowing for more blending and less total water treated. With this design approach, backwashing would only be required when sand or other material began to blind the media and create a pressure gradient.

The final treatment plant design was completed with booster pumps, yard piping, chemical feed piping and treatment building design. The City of Crane started the facility in April of 2015, and the water has met all primary contaminant levels since startup.

Project Leadership

- Daniel Albus, PE

- Brian Stephens, PE