Lubbock Preston Smith International Airpot

- aviation

- Lubbock, Texas

Project Scope

8,000 FT x 150 FT runway plus taxiways

Construction Type

New construction, reconstruction and rehabilitation

Project Delivery Method

Design-Bid-Build

Project Components

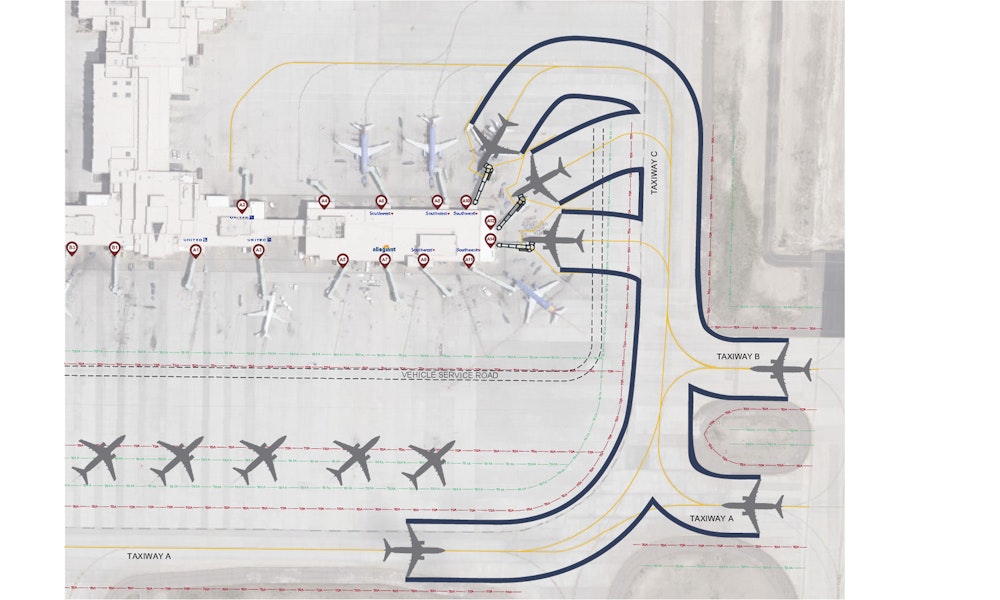

Design of taxiway and runway signage improvements, new precision approach path indicators (PAPI’s), relocation of Runway 26 MALSR and new Runway 8 MALSR, relocation of existing localizer for ILS, evaluation and design improvements of existing high intensity runway lights (HIRLs) and medium intensity taxiway lights (MITLs), upgrades to electrical vaults; utility relocation design; full-depth pavement design of Runway 8-26 and Taxiway J relocation; extension of Taxiways K, G, and J and Taxiway P to accommodate for Runway 8-26 extension; design of runway stormwater edge drain; extension of airport perimeter fence; extension of airport perimeter road; construction administration and RPR services

The purpose of this project was two-fold: to reconstruct pavement that was more than 25 years old and to improve airfield safety by remediating a “hot spot” resulting from intersecting runways. During the course of this project, Parkhill had to relocate a 72-inch water supply line, a 20-inch high-pressure gas line, and a major electrical duct bank. All of these utilities were relocated to a deeper depth and designed to accommodate aircraft loading since each crosses beneath the extended runway.

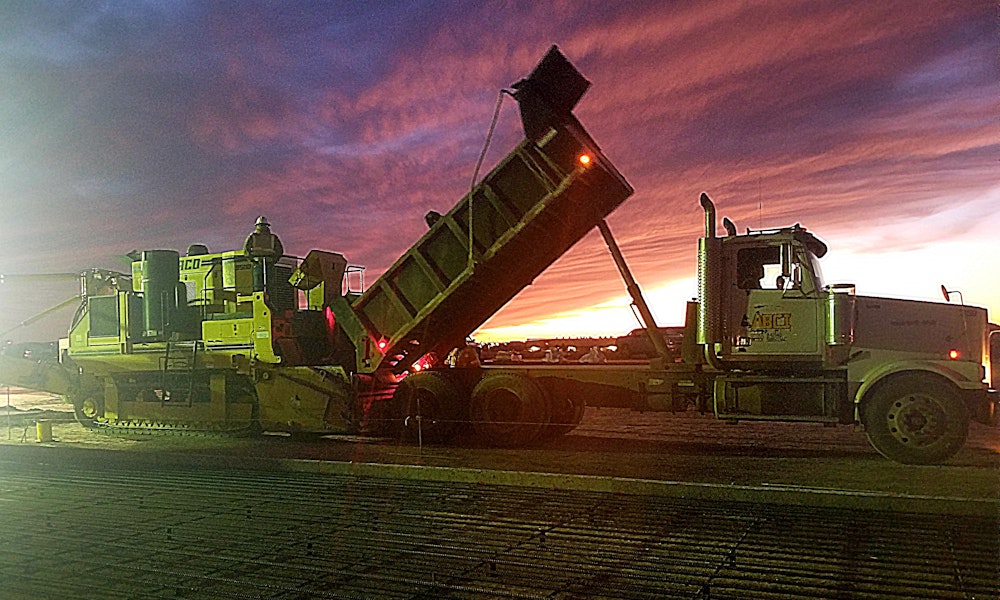

Pavement work included extending Runway 08/26 and Taxiway J, construction of the new Taxiways G and P, overlay of the existing runway, and the extension of the airport perimeter road. The all-new, full-strength pavement was composed of 16-inch P-501 concrete on 4-inch P-401 asphalt.

This project was unique in that the existing runway pavement was not fully removed and replaced. Utilizing heavyweight deflectometer and ground-penetrating radar data – in conjunction with standard geotechnical boring information – the Parkhill team determined that the existing pavement section was sound and could perform well as a base for the new pavement. The unbonded overlay design included a 2-inch P-401 hot mix asphalt bond breaker, a heavy-duty drainage fabric interlayer, and 8 inches of jointed P-501 concrete pavement. A parallel-edge drainage system was installed along all new pavements and along the overlaid runway.

Finally, the project required detailed coordination and communication for the relocation of the FAA-owned MALSR, glide slope, and localizer as well as installation of new PAPI-4s, edge lighting, and airfield signage.