El Paso Water

- treatment

- El Paso, Texas

Project Scope

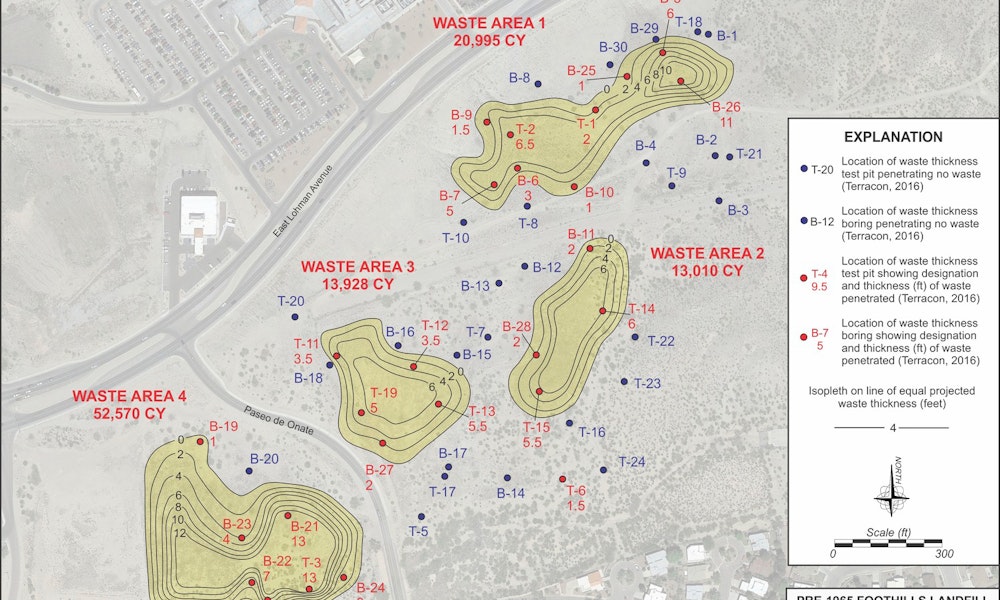

3.7 acres of concrete-lined sludge drying beds

Construction Type

Replacement

Project Delivery Method

Design-Bid-Build

Project Components

Concrete-lined sludge drying beds, Type K concrete, sludge piping

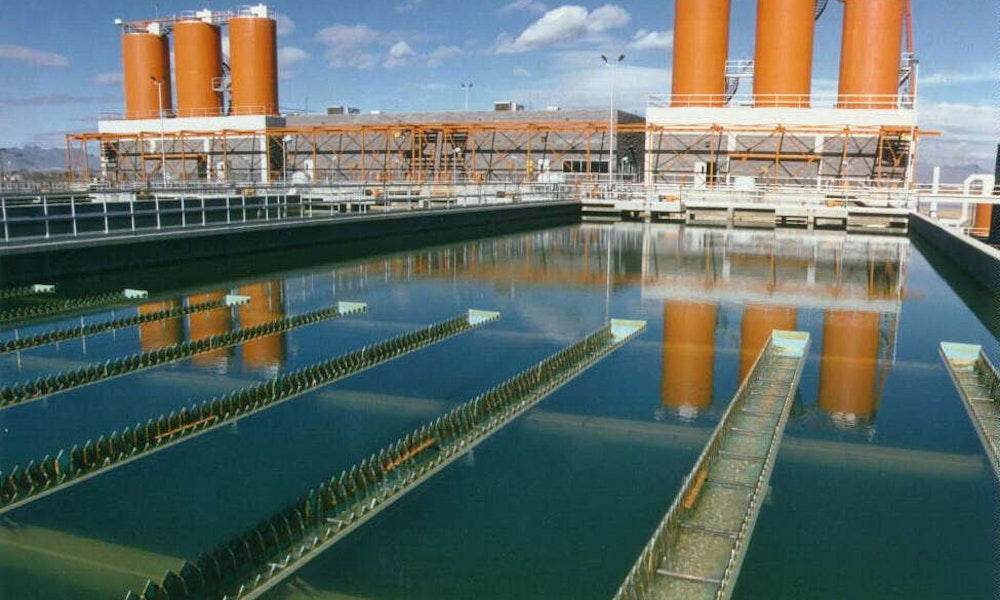

Parkhill designed the Fred Hervey Water Reclamation Plant, which was placed online in 1985. This facility uses a unique treatment process designed to treat up to 10 MGD of wastewater to drinking water quality and then inject it into the ground for future use. Besides recharging the Hueco Bolson, some of the reclaimed water is used to power generation and for irrigation.

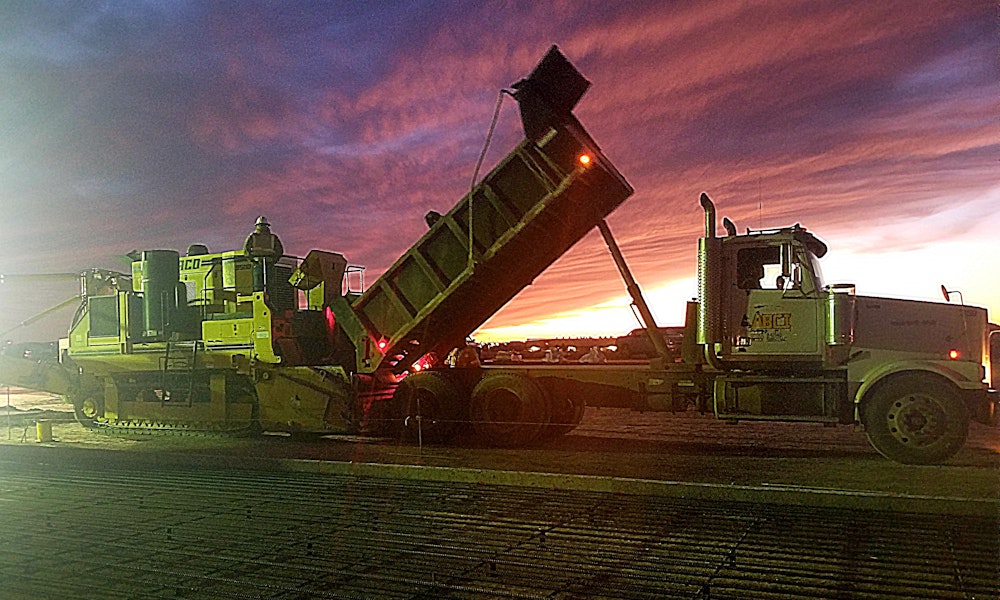

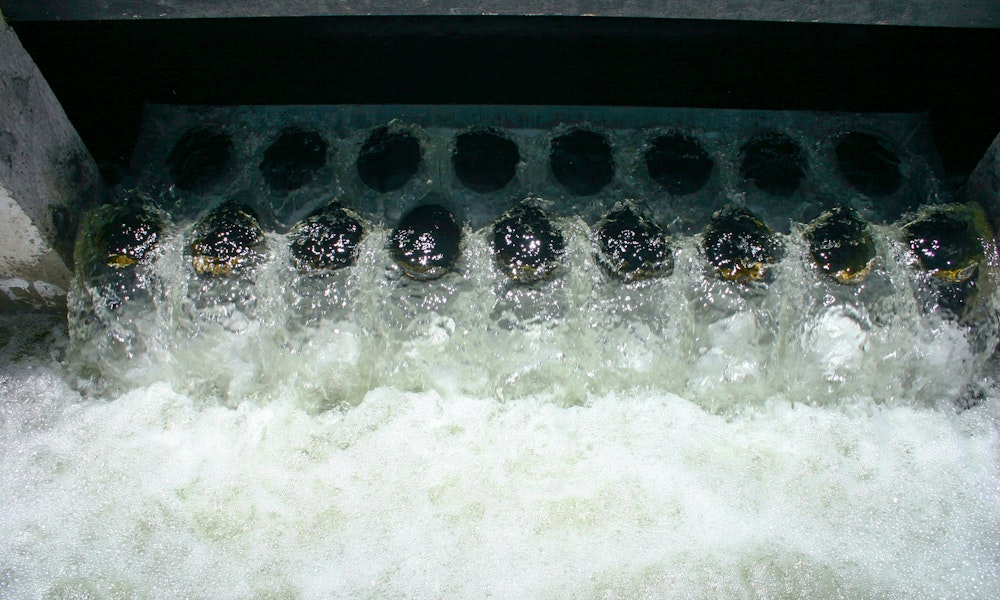

One of the final steps in the 11-step treatment process is letting the sludge dry out on lined sludge beds for a minimum of 90 days after going through the clarifiers. The sludge beds original to the plant were constructed with a clay liner covered by a soil cushion and stayed in service for 33 years.

When the original clay-lined beds had begun to deteriorate, Parkhill was selected to evaluate different liner options and ultimately decided to replace them with a shrinkage-compensating concrete lining. Along with the new liner material, Parkhill proposed a new layout of the sludge beds to El Paso Water to maximize the surface area of the beds. This use of shrinkage-compensating concrete lining minimizes joints and allows larger slabs to be poured for the new beds. The material also provides abrasion resistance when the sludge is scraped out of the beds for disposal. Each slab pour takes about 210 cubic yards of concrete, and there will be 24 different pours to make up the eight beds. The walls between each bed will replace the earthen berms providing a larger bed area and more drying capacity.

Fred Hervey Sludge Bed Replacement on Parkhill for Vimeo