El Paso Water

- treatment

- El Paso, Texas

Construction Type

Improvements

Project Delivery Method

Design-Build

Project Components

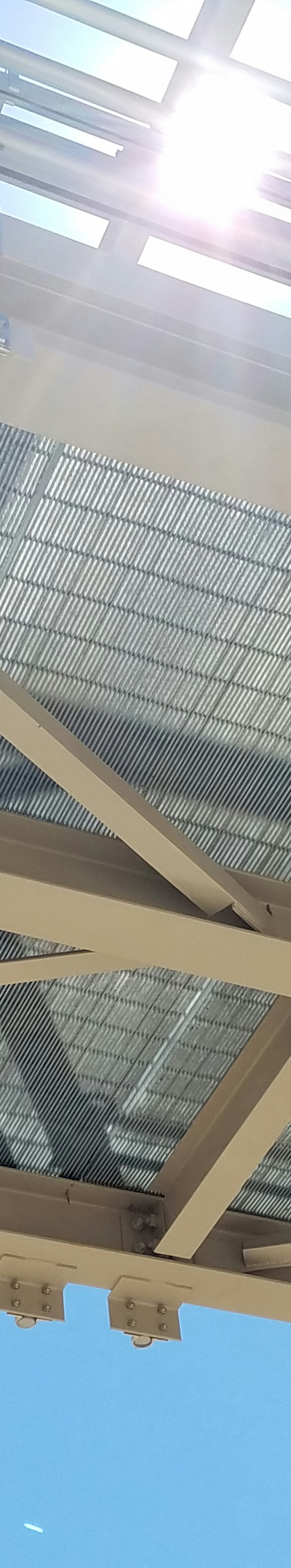

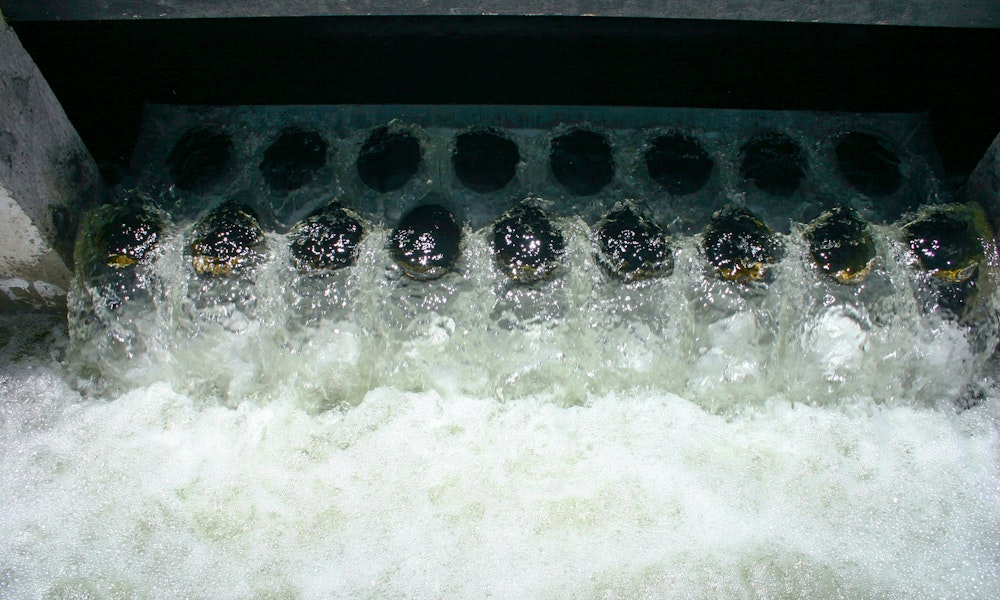

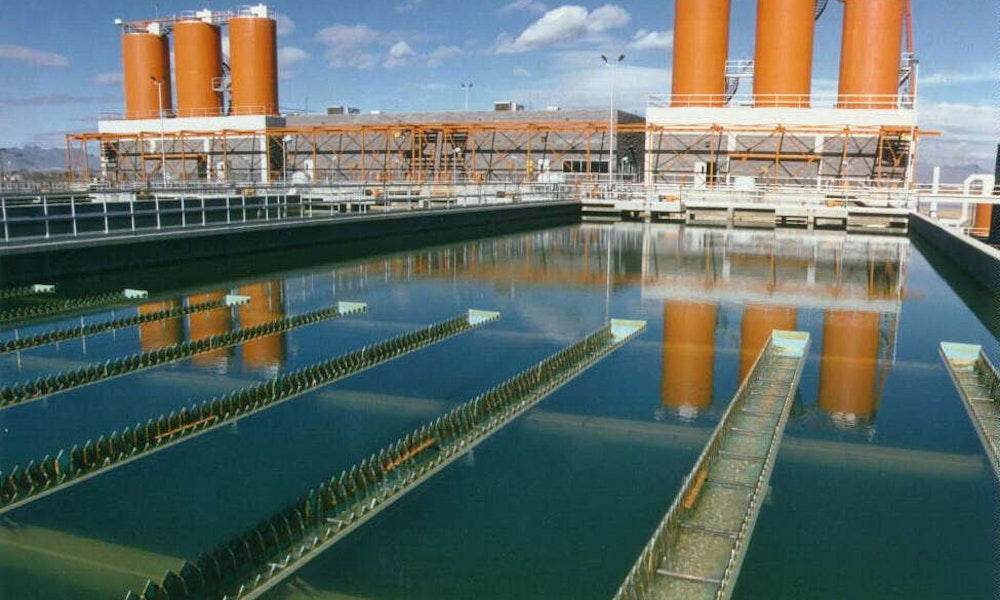

Bridge crane, monorail conveyance system, an outdoor elevated landing area for hoisting equipment, structural steel and foundation for the elevated landing area, installation of an access doorway for the monorail, and removable guard rails around the flocculation basins

Parkhill was tasked with a perplexing problem in the Upper Valley Water Treatment Plant: how to smoothly install a long traveling bridge crane over the operating flocculation basins in a tight building without harming light fixtures and other hardware. Before, operations personnel had to “muscle it out” and cart items down a stairwell that made two 90-degree turns or convey it manually to another building.

Replacing equipment under a pitched roof was difficult. Parkhill provided design, bid and construction phase services to ensure the crane system was suitable for moving equipment weighing up to a half ton outside to a monorail that can lift up to a ton of equipment. With the monorail hoist and platform, workers can lower items over the edge rather than going down several flights of stairs and back up.

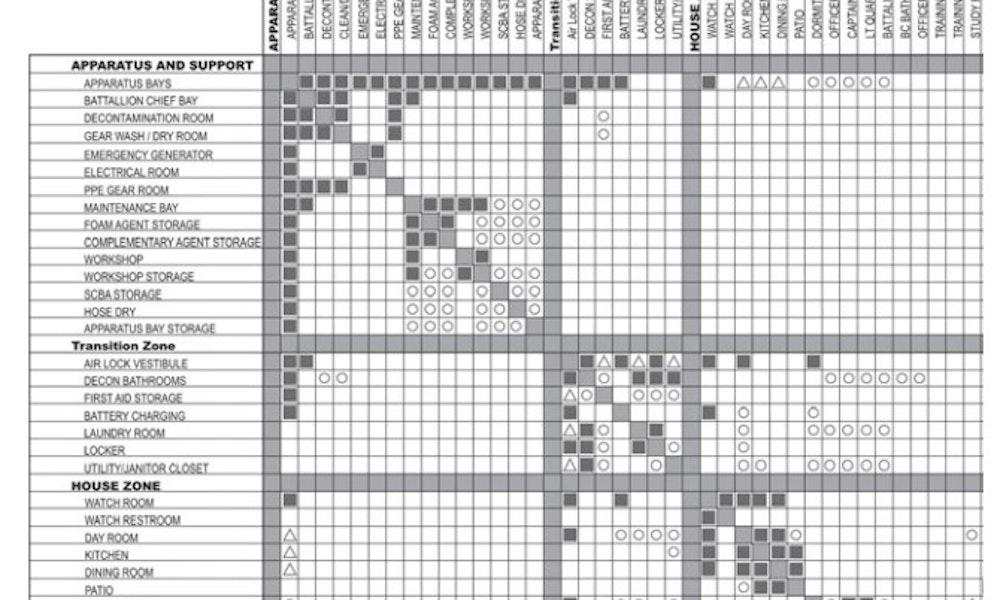

Parkhill also analyzed every piece of equipment, including flocculator shafts, motors, gearboxes, and inclined plates, and realized a smaller size of crane and monorail could do the job. This and recommending eliminating a second bridge crane on top of one of the sedimentation basins resulted in saving El Paso Water a significant amount of money.