El Paso Water

- treatment

- El Paso, Texas

Project Scope

110-foot-diameter clarifiers

Construction Type

Clarifier upgrades

Project Delivery Method

Design-Bid-Build

Project Components

Revamp of four primary clarifiers, installation of air monitors for hydrogen sulfide gas, repair of concrete launder troughs, coatings, electrical upgrades, polymer feed system equipment

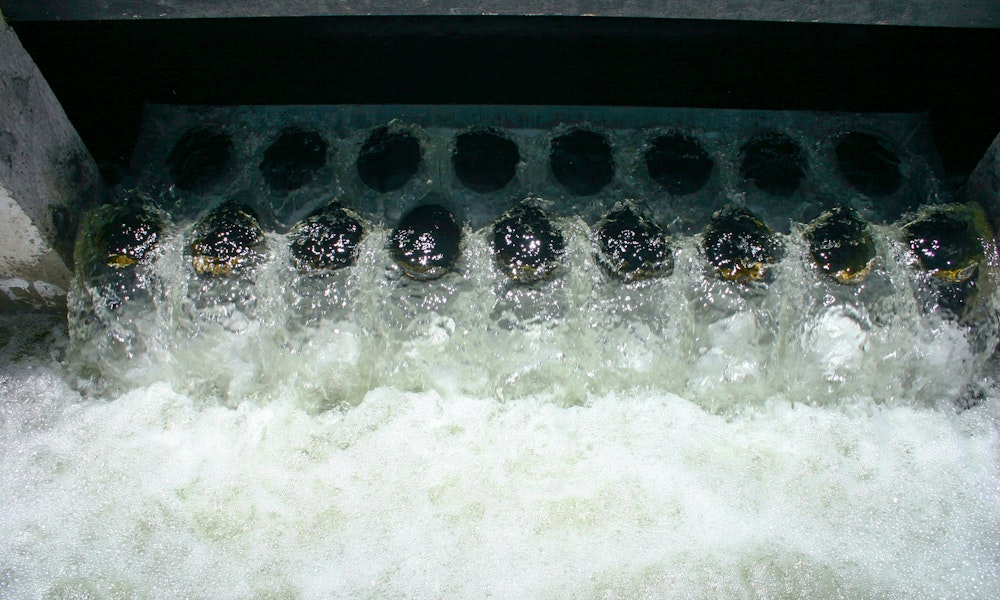

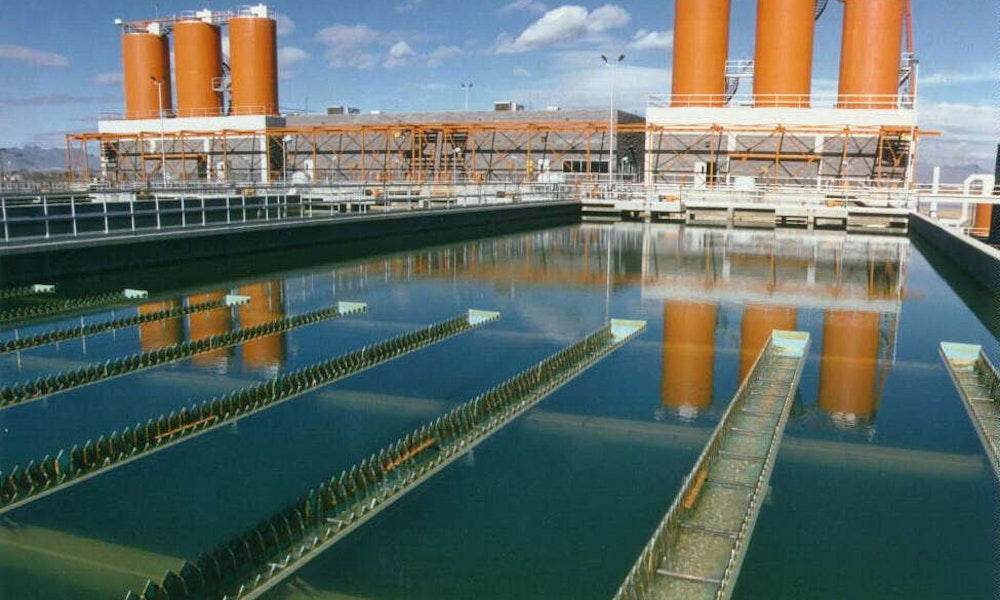

Design, bid, and construction phase services were provided for the revamp of four primary clarifiers at the Haskell R. Street Wastewater Treatment Plant. Each of the clarifiers at the plant had reached its mechanical lifespan of 20-plus years. Potentially dangerous conditions in the clarifiers were attributed to the existing air scrubber system being out of commission. With the subsequent inability to remove the high concentration of H2S from within the clarifiers, the mechanical equipment and steel catwalks began to deteriorate exponentially. With the air system out of service, plant personnel were unable to safely enter the clarifiers due to the deteriorating catwalks. These conditions left the plant personnel unable to perform their required maintenance, which then accelerated deterioration and added to the equipment failure. Parkhill provided a budget/procurement plan, final design documents, bid phase, and construction administration.

During the rehabilitation, Parkhill resolved temporary power sources and coordinated replacing equipment carefully and in a limited amount of time. The MCC-17 is the electrical hub for all four clarifiers. Before switching to a new MCC-17, temporary power had to be in place for the clarifiers. Also, 26 valves inside the sludge building had to be replaced. While some could be replaced with the clarifiers in limited operation, other valves required the clarifiers to be off-line. Coordinating with plant personnel, the valves were replaced in a small window of time. Six projects were scheduled to be under construction at the Haskell WWTP from 2016 to 2020. Coordination was critical to not interfere with the other projects.

The project included:

- Full equipment replacement

- New odor control/collection system

- Explosion-proof lighting and fiberglass reinforced plastic (FRP) ductwork

- Electrical/controls upgrades

- Air monitors for hydrogen sulfide gas

Services Provided

Design, bid phase services, and construction administration