City of Big Spring

- treatment

- Big Spring, Texas

Project Size

11.4 million gallons per day

Construction Type

Improvements

Project Delivery Method

Design-Bid-Build

Project Components

Hydraulic design, process design, grit and screenings design, new building

The City of Big Spring hired Parkhill in 2014 to design the second phase of the major upgrade to the city’s wastewater treatment plant (WWTP). The upgrades were required so that the city could continue to provide treated effluent to the Canadian River Municipal Water District (CRMWD) for potable reuse.

The project consisted of three major components:

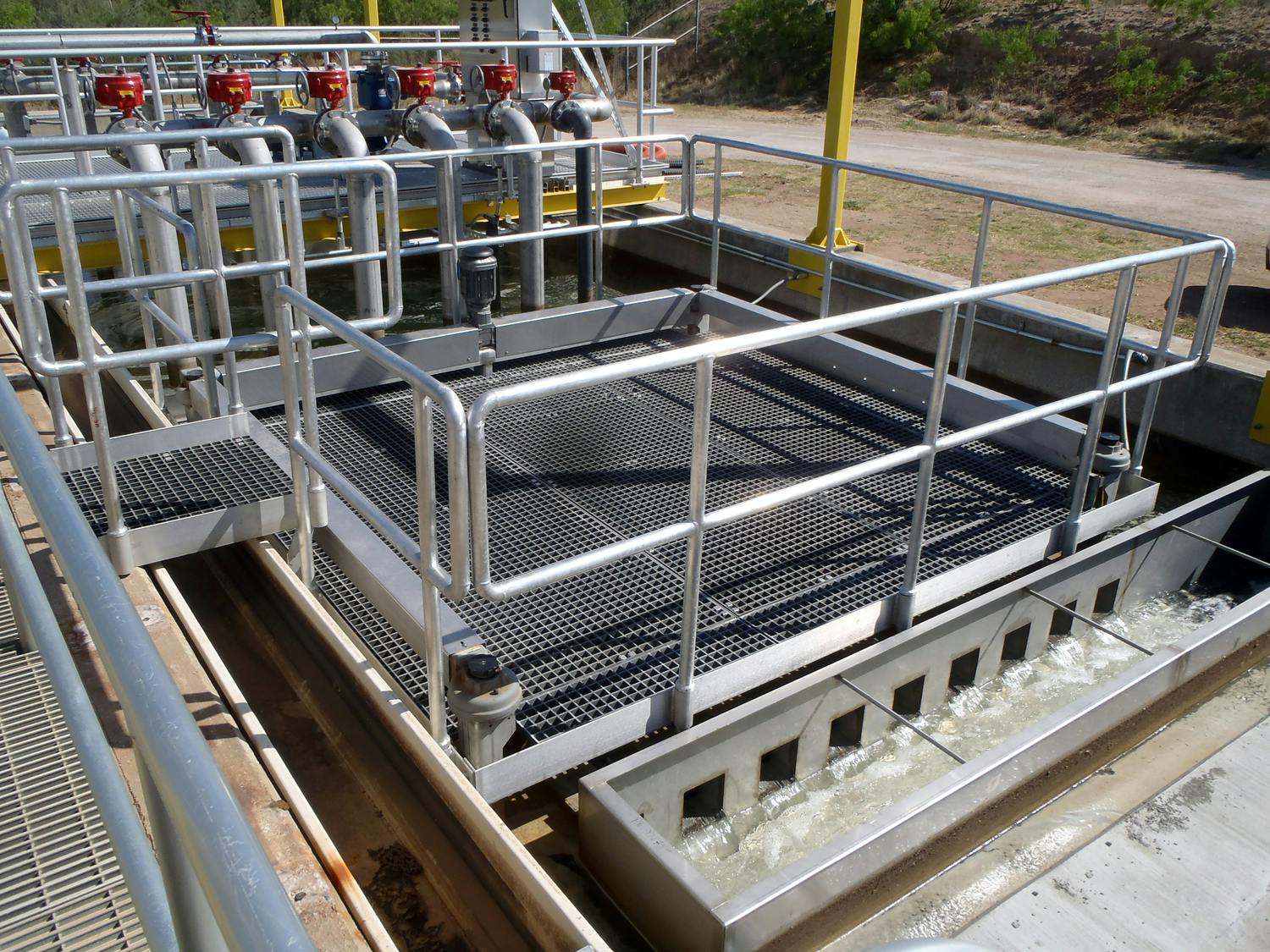

New Headworks Facility

Includes a new raw sewage submersible lift station to pump the 3.8 million gallons per day (MGD) average flow, and the 11.4 million-gallons-per-day peak flows form the City of Big Spring. Course and fine screens as well as a new Eutek Grit System were installed to screen debris out of the wastewater prior to entering the plant.

New Aeration Blowers

Three new aeration blowers were installed at the aeration basin. The new blowers are much more efficient with power usage and produce much less heat than the original blowers.

New Sludge Belt Filter Press

A new 2-meter Ashbrook Belt Filter Press was installed to dewater both waste activated and primary sludge from the WWTP process without having to send the sludge to the existing digesters for additional treatment.

Parkhill proceeded with design, bidding and construction of the headworks improvements to the plant. The project was completed within two months of the original 15-month schedule due to weather days and other minor issues. The project was a rehabilitation of an existing plant and experienced approximately 3 percent of the original project bid in change orders — most of which were minor utility issues uncovered during the excavation portions of the project.

Services Provided

Environmental engineering, civil engineering, architectural design, electrical and controls design

Project Leadership

At Parkhill, We're Designing and Building for

Your Tomorrow

El Paso Water

- treatment

- El Paso, Texas

Project Size

39 million gallon per day wastewater treatment plant. 16,200 square-foot, two-story administration/laboratory/maintenance facility

Construction Type

New

Project Delivery Method

Design

Project Components

51 MGD influent lift station, screening, grit removal, pre-aeration, an enclosed headworks with air scrubbers for odor control, cover primary clarifiers with air scrubbing, primary sludge pumps, activated sludge system with fine bubble diffusers and four 1,250 HP single stage blowers, four 140-foot final clarifiers, gravity belt thickening of waste activated sludge, anaerobic digestion, filter press dewatering, a distributed control system, a 500 KW digester gas fed co-generation unit, two 1,500 KW natural gas fed engine generators, and a two-story administration/laboratory/maintenance facility

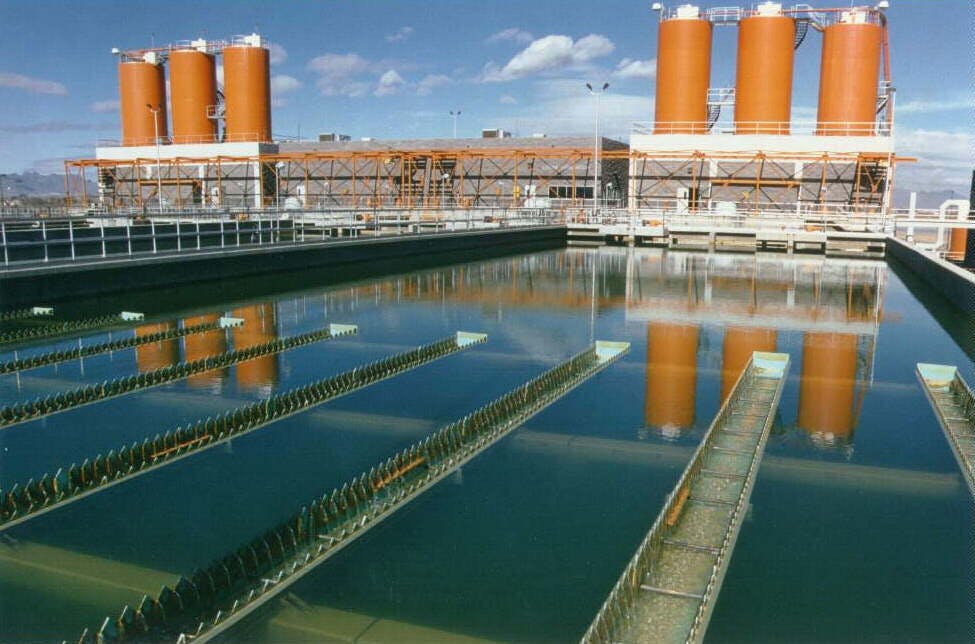

The beauty of the award-winning Roberto R. Bustamante Wastewater Treatment Plant is that the treated wastewater can be used in multiple ways.

The Bustamante WTP provides reclaimed water to either the Riverside Canal, which helps with industrial irrigation, or the Riverside Drain to serve the Rio Bosque Wetlands Preserve. The plant could also provide reclaimed water to industries in the Riverside Industrial Park. It originally was referred to as the Southeast Wastewater Treatment Plant for the Lower Valley area of El Paso. The Bustamante plant came online with a permitted capacity of 39 million gallons per day and currently, the plant cleans approximately 27 million gallons of wastewater per day.

The plant uses advanced secondary treatment through state-of-the-art extended aeration activated sludge processes, biological nitrification, and caustic air scrubbers for odor control. The dual-use project has won El Paso Water several awards by such groups as the National Association of Clean Water Agencies and the EPA.

Awards

- National Association of Clean Water Agencies (NACWA) Peak Performance Platinum Award

- 17 NACWA Gold Awards, and 2 NACWA Silver Awards

- 2005 Water Environment Association of Texas Municipal Wastewater Treatment Plant of the Year

Project Leadership

At Parkhill, We're Designing and Building for

Your Tomorrow

City of Lubbock

- treatment

- Lubbock, Texas

Project Size

15 million gallons per day with expansions up to 50 MGD

Construction Type

New building and renovations

Project Delivery Method

Design-Bid-Build

Project Components

- 225-million-gallon terminal storage

- 2,150-square-foot flow control building

- 5,000-square-foot high-service pump station building

- 48,000-square-foot multi-level treatment and administration complex

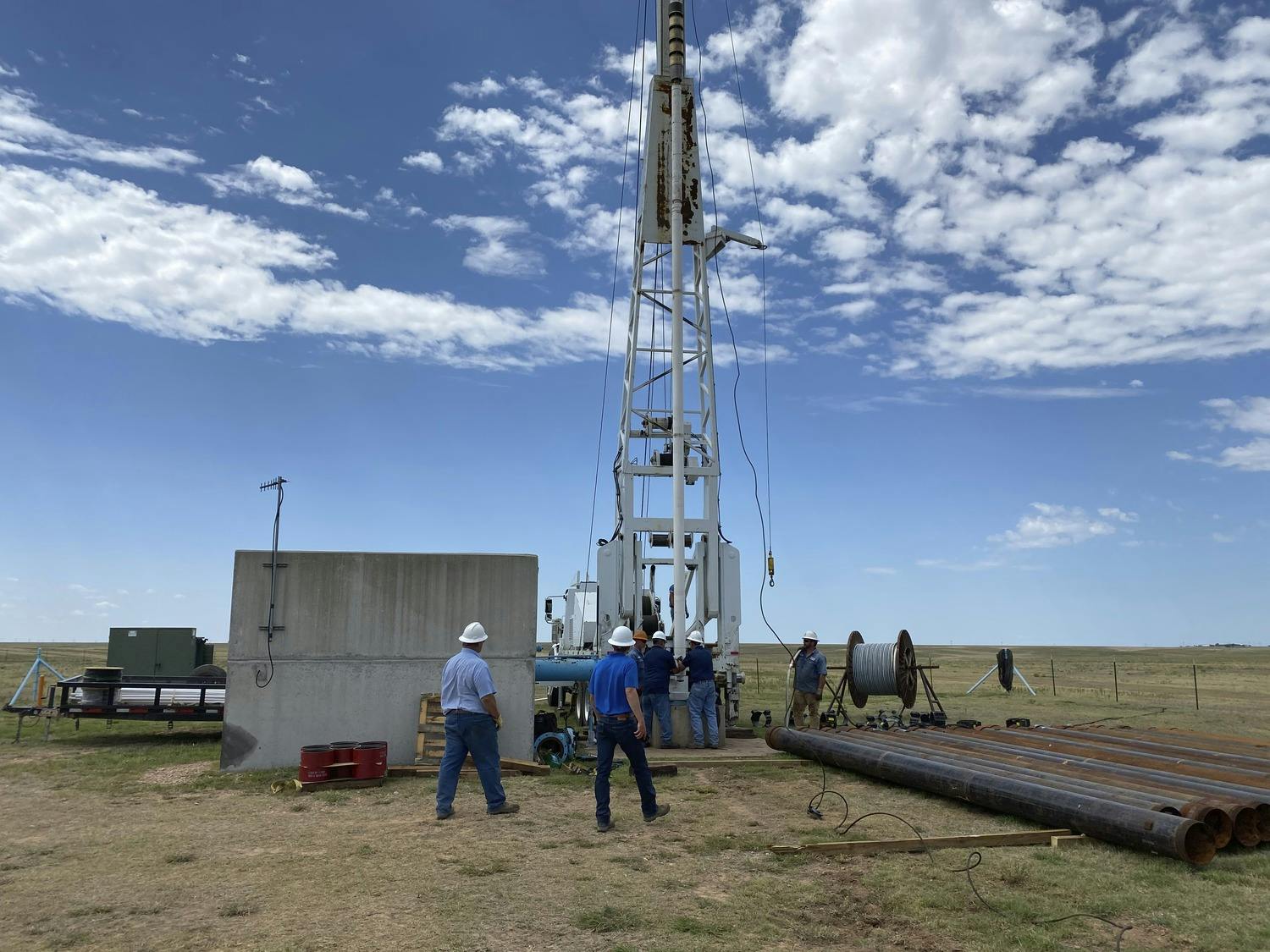

Due to prolonged drought conditions and its detrimental effect on Lake Meredith, the City of Lubbock’s primary source of drinking water was in need of a secondary water supply source to aid in supplying water. The city chose Parkhill to begin the design and construction of a new water treatment plant on the southeast side of Lubbock. The plant would treat surface water from Lake Alan Henry and would be rated for approximately 15 million gallons per day (MGD) with planned expansions to 50 MGD.

The Parkhill team designed the new South Water Treatment Plant site including a 225-million-gallon terminal storage reservoir, chemical and physical pretreatment facilities and a membrane filtration plant for primary treatment of the potable water. Not only did the Parkhill Team choose to use membrane filtration because of the plant’s small footprint, but also to plan for the city’s future water reuse. This new plant supplements the city’s water needs by being one of three water sources for the City of Lubbock.

The City of Lubbock South Water Treatment Plant was constructed on time with only minor weather delays and less than 1% in change orders. The plant includes a full services administration building with a large laboratory for all of the plants testing needs, offices for the operators, a large meeting room for staff training, and other key office needs. The building is planned for future expansions up to 50 MGD and will serve the citizens of Lubbock well for years into the future.

Project Leadership

At Parkhill, We're Designing and Building for

Your Tomorrow

City of Crane

- treatment

- Crane, Texas

Project Size

1.3 MGD

Construction Type

Improvement

Project Delivery Method

Design-Bid-Build

Project Components

Hydraulic design, piping, architectural and structural, arsenic treatment process

In 2006, the Texas Commission on Environmental Quality (TCEQ) began enforcing a new arsenic maximum contaminant level (MCL) of 0.01 mg/L. Crane, Texas, had historical arsenic levels just above the MCL at 0.013 mg/L. The city entered many compliance plans with TCEQ but eventually came under direct enforcement from the Environmental Protection Agency. The City of Crane contacted Parkhill to find a treatment solution for their arsenic problem.

In order to develop a successful water treatment solution for Crane, Parkhill examined the existing water conditions of the city before beginning the plant design. Historically, the City of Crane has had a stable water use flow. The city pumps water from over 50 wells through 3 pump stations before distributing to the customers. The results indicated an average water flow of approximately 1 million gallons per day (MGD) and a peak of 2 MGD of water usage. Water is precious in Crane, because of the high cost to bring it into the city. As a result, Parkhill saw a need to minimize the rejection or backwash flow, and used these flow parameters to design the arsenic water treatment plant.

Parkhill presented the city with two options to remove arsenic from their water. The City of Crane chose to implement an iron-adsorption technology that would run water through two large pressure filters containing the adsorption media. The adsorption technology was able to treat the arsenic down to lower levels allowing for more blending and less total water treated. With this design approach, backwashing would only be required when sand or other material began to blind the media and create a pressure gradient.

The final treatment plant design was completed with booster pumps, yard piping, chemical feed piping and treatment building design. The City of Crane started the facility in April of 2015, and the water has met all primary contaminant levels since startup.

Project Leadership

- Daniel Albus, PE

- Brian Stephens, PE

At Parkhill, We're Designing and Building for

Your Tomorrow

City of Big Spring

- treatment

- Big Spring, Texas

Project Size

3.8 MGD average, 11.4 MGD peak

Construction Type

New

Project Delivery Method

Design-Bid-Build

Project Components

New aeration line, new aeration diffusers, new effluent cloth media filters

Due to the current drought situation and failing historic surface water sources, the Colorado River Municipal Water District (CRMWD) began to look for alternative water sources in order to meet their clients’ water demands. As a result, the CRMWD reached the decision to build a potable water reuse plant in the City of Big Spring that would collect and treat up to 2 million gallons of treated effluent from the City of Big Spring’s Wastewater Treatment Plant (WWTP).

Parkhill was tasked by the City of Big Spring with evaluating the city’s current WWTP and designing improvements to the facility that would facilitate the delivery of high-quality effluent to the new reuse facility. Upon completing the evaluation, Parkhill recommended and designed improvements to the 25-year-old plant’s aeration basin and effluent filters. The chosen improvements were critical for the plant to supply effluent capable of reuse to the CRMWD plant and to maintain TPDES compliance. This was particularly important because the city’s WWTP did not have effective screening, grit removal or primary clarification. Due to time constraints of the new reuse facility, the new filters would be the first of a two-phase project to upgrade the City of Big Spring WWTP and would provide the effluent polishing to reduce turbidities and allow the new potable reuse membrane plant completed by CRMWD to run more efficiently.

The chosen WWTP improvements included new diffusers in the aeration basins, a new air supply line and steel truss structure, and removal of sludge from the aeration basin. Parkhill also designed the retrofit of the existing traveling bridge effluent filters with new cloth media filters. The new cloth filters were so efficient that the new filters took a 50 percent footprint of the original traveling bridge filters.

Services provided included wastewater treatment process design, wastewater treatment hydraulic design, civil site design, structural engineering, electrical engineering, construction and inspection services.

Project Leadership

At Parkhill, We're Designing and Building for

Your Tomorrow

El Paso Water

- treatment

- El Paso, Texas

Project Size

3.7 acres of concrete-lined sludge drying beds

Construction Type

Replacement

Project Delivery Method

Design-Bid-Build

Project Components

Concrete-lined sludge drying beds, Type K concrete, sludge piping

Parkhill designed the Fred Hervey Water Reclamation Plant, which was placed online in 1985. This facility uses a unique treatment process designed to treat up to 10 MGD of wastewater to drinking water quality and then inject it into the ground for future use. Besides recharging the Hueco Bolson, some of the reclaimed water is used to power generation and for irrigation.

One of the final steps in the 11-step treatment process is letting the sludge dry out on lined sludge beds for a minimum of 90 days after going through the clarifiers. The sludge beds original to the plant were constructed with a clay liner covered by a soil cushion and stayed in service for 33 years.

When the original clay-lined beds had begun to deteriorate, Parkhill was selected to evaluate different liner options and ultimately decided to replace them with a shrinkage-compensating concrete lining. Along with the new liner material, Parkhill proposed a new layout of the sludge beds to El Paso Water to maximize the surface area of the beds. This use of shrinkage-compensating concrete lining minimizes joints and allows larger slabs to be poured for the new beds. The material also provides abrasion resistance when the sludge is scraped out of the beds for disposal. Each slab pour takes about 210 cubic yards of concrete, and there will be 24 different pours to make up the eight beds. The walls between each bed will replace the earthen berms providing a larger bed area and more drying capacity.

Fred Hervey Sludge Bed Replacement on Parkhill for Vimeo

Project Leadership

At Parkhill, We're Designing and Building for

Your Tomorrow

El Paso Water

- treatment

- El Paso, Texas

Project Size

110-foot-diameter clarifiers

Construction Type

Clarifier upgrades

Project Delivery Method

Design-Bid-Build

Project Components

Revamp of four primary clarifiers, installation of air monitors for hydrogen sulfide gas, repair of concrete launder troughs, coatings, electrical upgrades, polymer feed system equipment

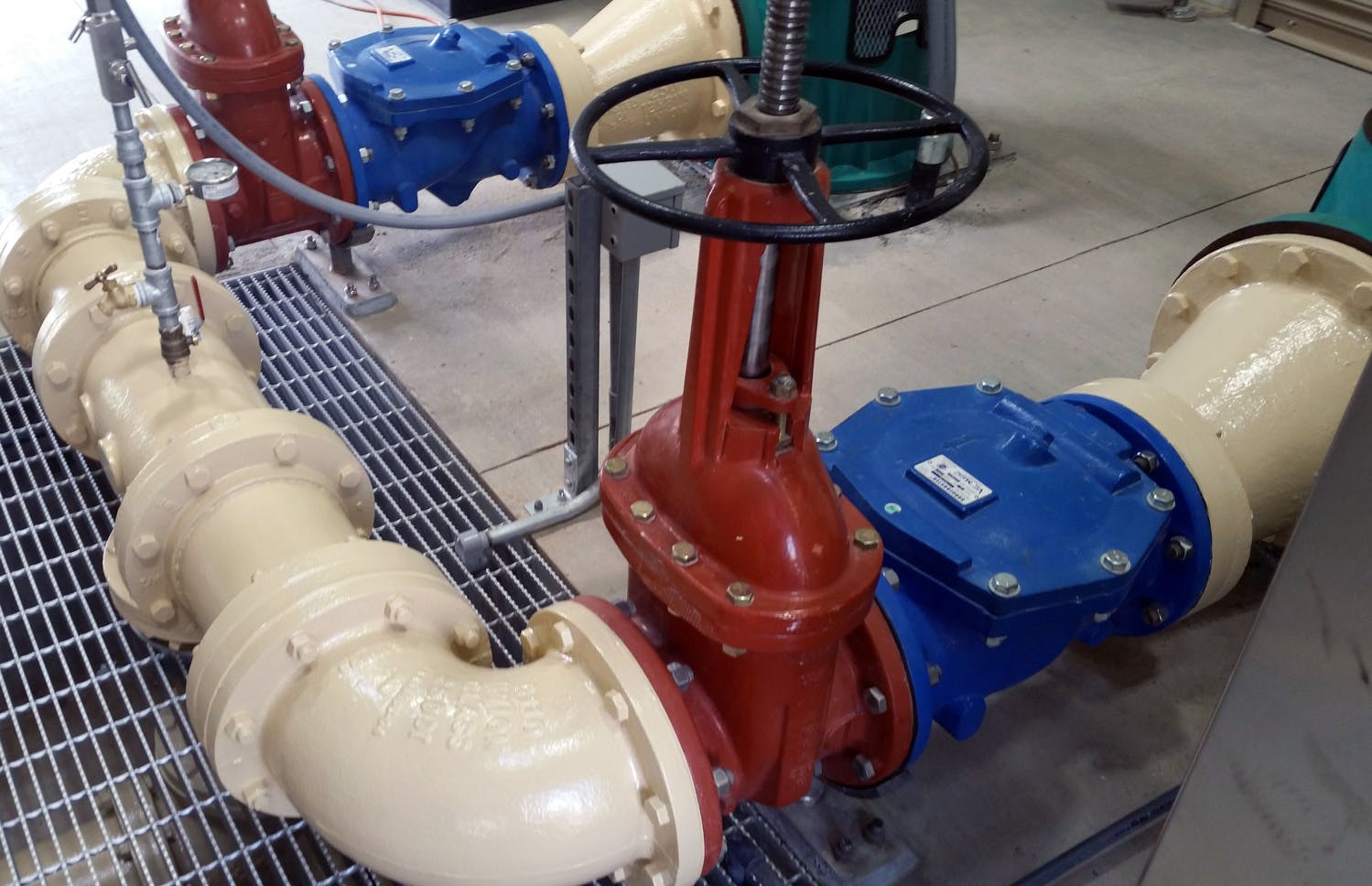

Design, bid, and construction phase services were provided for the revamp of four primary clarifiers at the Haskell R. Street Wastewater Treatment Plant. Each of the clarifiers at the plant had reached its mechanical lifespan of 20-plus years. Potentially dangerous conditions in the clarifiers were attributed to the existing air scrubber system being out of commission. With the subsequent inability to remove the high concentration of H2S from within the clarifiers, the mechanical equipment and steel catwalks began to deteriorate exponentially. With the air system out of service, plant personnel were unable to safely enter the clarifiers due to the deteriorating catwalks. These conditions left the plant personnel unable to perform their required maintenance, which then accelerated deterioration and added to the equipment failure. Parkhill provided a budget/procurement plan, final design documents, bid phase, and construction administration.

During the rehabilitation, Parkhill resolved temporary power sources and coordinated replacing equipment carefully and in a limited amount of time. The MCC-17 is the electrical hub for all four clarifiers. Before switching to a new MCC-17, temporary power had to be in place for the clarifiers. Also, 26 valves inside the sludge building had to be replaced. While some could be replaced with the clarifiers in limited operation, other valves required the clarifiers to be off-line. Coordinating with plant personnel, the valves were replaced in a small window of time. Six projects were scheduled to be under construction at the Haskell WWTP from 2016 to 2020. Coordination was critical to not interfere with the other projects.

The project included:

- Full equipment replacement

- New odor control/collection system

- Explosion-proof lighting and fiberglass reinforced plastic (FRP) ductwork

- Electrical/controls upgrades

- Air monitors for hydrogen sulfide gas

Services Provided

Design, bid phase services, and construction administration

Project Leadership

At Parkhill, We're Designing and Building for

Your Tomorrow

El Paso Water

- treatment

- El Paso, Texas

Project Size

17.5 million gallons per day

Construction Type

Upgrade

Project Delivery Method

Design-Bid-Build

Project Components

Study of new filtering technology, launder covers

After 20 years of polishing treated effluent from the Hickerson WRP, the existing traveling bridge sand filters had become increasingly difficult to maintain and repair due to a lack of available replacement parts.

Parkhill developed a pilot protocol to evaluate four different cloth media filter technologies that could replace the outdated sand filters. Once the protocol was developed, Parkhill performed pilot testing of the four technologies and evaluated them based on removal efficiency, backwash efficiency, and the ability to handle upsets. The pilot testing showed that two of the technologies tested could produce water with better quality than the existing system. The effluent turbidity of the two technologies was roughly half of that produced by the existing filters Site visits to full-scale implementations of the technologies were conducted along with EP Water operations in order to finalize the technology selection.

Once the preferred technology was selected, Parkhill developed a design to retrofit the cloth media technology into the existing filtration basins in the plant. The resulting design will enable the plant to treat the full plant capacity in two basins while leaving one existing sand filter in place for emergency use.

The project also included the design of launder covers to be installed on the secondary clarifiers at the plant. These covers will prevent algae growth on the launders and subsequent conveyance of algae to the filters.

Services Provided

Pilot Study, Process, Hydraulics, Electrical, Instrumentation and Controls, General Civil, Structural, Construction Period Services

Project Leadership

At Parkhill, We're Designing and Building for

Your Tomorrow

El Paso Water

- treatment

- El Paso, Texas

Project Size

10 million gallons per day

Construction Type

New

Project Delivery Method

Design-Bid-Build

Project Components

Wastewater Treatment, Water Treatment, Ozone, PACT, Biological Filtration, Injection Wells, Storage Tanks, Pumping

The Fred Hervey Water Reclamation Plant in Northeast El Paso was the first in the nation to take domestic wastewater and produce potable water that meets state and nation drinking water standards through a rigorous treatment process. Working with El Paso Water, Parkhill recommended the development of wastewater facilities that could be used to reclaim wastewater for injections into the city’s largest subsurface water source, the Hueco Bolson.

Environmental and water quality data were studied extensively and the results were presented along with a plan to implement a treatment process. Public acceptance of the plan was achieved through a citizen outreach program. Parkhill and EP Water presented the plan to the U.S. Environmental Protection Agency who approved the plan and provided a $21 million grant to the city to construct the $33 million plant.

Built in 1985, the plant sends the wastewater through 11 processes that purify the water through a combination of physical, chemical, and biological treatment. Online analyzers evaluate the effectiveness of the process along the way.

The initial project employed a distribution system that conveyed the treated water to 10 injection wells, strategically placed throughout the Hueco Bolson. In addition to the recharge of the aquifer, the plant also supplies cooling water to a local power plant, spread basins, and a golf course – 100 percent of the effluent produced is used for aquifer recharge or to offset using new water pumped from the Hueco Bolson.

Read more about the original project

32 Years of Potable Reuse

Services Provided

Process, hydraulics, general civil, architectural

Awards

National Association of Clean Water Agencies Gold Award

Project Leadership

At Parkhill, We're Designing and Building for

Your Tomorrow

El Paso Water

- treatment

- El Paso, Texas

Project Size

40 million gallons per day facility constructed in 1993; updgraded to 60 million gallons per day in 2001

Construction Type

Water Treatment Plant

Project Delivery Method

Design/construction period services

Project Components

Preliminary engineering study, environmental assessment and BECC certification procedure, design and construction along with a national firm

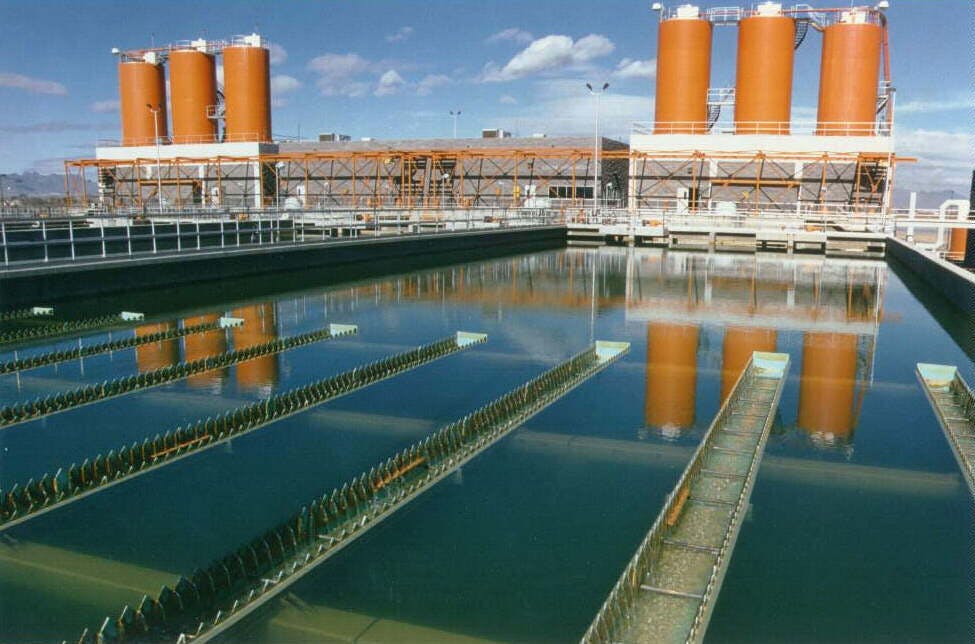

Of all the engineering projects submitted in 1995 for the Engineering Excellence Awards, only one was chosen in the entire nation. The Jonathan W. Rogers Water Treatment Plant, a state-of-the-art facility located in El Paso and designed by Parkhill, was named the prestigious Grand Award Winner by the American Consulting Engineers Council.

The plant features several unique processes, including ozonation – something new to El Paso at the time – and biological activated carbon (BAC), a relatively new concept in America at the time. The plant, designed by Parkhill in association with a national firm, was placed online in 1993. The uniqueness of the design was that of common wall construction in the Rogers plant for efficient use of space. The project also employed a unique resource-sharing agreement between neighboring jurisdictions to provide residents with safe drinking water. Lower than anticipated construction and operating costs enabled the client to provide a more affordable treated water supply than planned.

The project timing was influenced by federal, state, and local entities with incentives, standards, and funding opportunities. The original 40 mgd plant cost $27 million to build. Parkhill designed upgrades to bring the plant capacity to 60 mgd in 2001 and is currently involved in expanding the plant to treat 80 mgd.

Awards

Grand Award Winner in the Engineering Excellence Awards

Project Leadership

At Parkhill, We're Designing and Building for

Your Tomorrow

City of Lamesa

- treatment

- Lamesa, Texas

Project Size

2.0 MGD

Construction Type

New

Project Delivery Method

Design-Bid-Build

Project Components

New headworks facility, aeration basin, secondary clarifiers, UV disinfection system, sludge dewatering belt press, new administration building, vehicle maintenance bay

The City of Lamesa hired Parkhill to design a new wastewater treatment plant to treat 2 million gallons per day (MGD) of raw wastewater. The new wastewater treatment plant was an activated sludge carousel facility capable of treating to stream discharge standards.

Major components of the project included a new headworks facility, aeration basin, secondary clarifiers, UV disinfection system, and a sludge dewatering belt press. In addition, Parkhill designed a new administration building for plant staff that included a laboratory for taking samples, UV disinfection, and sludge dewatering as well as a maintenance bay for servicing plant vehicles. The design of the plant fits on 3 acres of land.

Project Leadership

At Parkhill, We're Designing and Building for

Your Tomorrow

El Paso Electric

- treatment

- El Paso, Texas

Project Size

45-acre evaporation pond

Construction Type

Replacement and new construction

Project Delivery Method

Design-Bid-Build

Project Components

Sediment removal, excavation, cast-in-place concrete, electrical services, and installation of pump, pipe and liner

After observing some problems with the evaporative pond liner, El Paso Electric (EPE) hired Parkhill to perform an evaluation of the evaporation pond at the Newman Power Station. Over 40 years, the liner had begun to deteriorate and needed replacement as well as sediment removal which had reduced capacity. Upon completion of the report, Parkhill designed the 45-acre pond, which will be divided into 2 operational ponds with an 11-foot concrete wall. This will allow continual operation of the pond if either side needs to be taken offline. A 60-mil high-density polyethylene leak detection liner will be installed to replace the original 10 mil PVC liner.

The project will be completed in 2 phases, west and east pond. Both phases involve removing the old liner and a foot of sediment that had collected on the bottom of the pond. The sediment removal process involved pushing sediment into rows and piles where the plastic liner could be separated and disposed of properly. This process was completed in about 1 month. Upon completion, excavation will lower the pond bottom about 2 feet from its prior elevation and excavate a footing for the dividing wall which will span 870 feet across the pond.

This project also involves rerouting and combining 6 pipes of effluent entering the pond at one location at each pond. The combining of the effluent piping will provide one central location for effluent and pond management, giving EPE flexibility. The exit pipes will provide metering for the site and will run over 1,000 feet to irrigation piping. The metering and controls were centrally located to provide ease of management and valve operation for irrigation. Irrigation pumping will be managed through electronic water depth gage, flow meters, and variable frequency pumps.

Project Leadership

At Parkhill, We're Designing and Building for

Your Tomorrow

City of Lubbock

- treatment

- Lubbock, Texas

Project Size

20 miles of treated water line across elevation changes and eight major crossings, including Interstate 27

Parkhill was contracted by the City of Lubbock to provide design services for the final phase of the greater Lake Alan Henry Water Supply Project. This consisted of approximately 20 miles of treated water line across elevation changes and eight major crossings, including Interstate 27. The project was completed in two phases, allowing the construction to be coordinated with adjacent housing developments along the route.

For the project, Parkhill assembled an extensive working model of the 20-mile water line. This model simulated laminar flow conditions and allowed the design team to identify and design an effective surge suppression system. The elevation changes along the route of the water line caused more than 60 psi in pressure loss from one end to the other. Using the model, our design team simulated the current and future flows of each of the three pump stations and was able to accurately depict necessary control valve open and close times. They were also able to predict how the mechanisms would act during the most likely surge scenario to occur during a possible loss of power to the system.

Of all the major crossings encountered, the 735-foot tunnel and bore underneath Interstate 27 was the most difficult. To overcome this challenge, Parkhill utilized a steel liner plate in lieu of typical steel casing so that adjustments could be made for grade as the tunnel was completed. Once finished, a 48-inch concrete line was installed and the annular space of the tunnel was backfilled. Additionally, all of the major crossings required extensive pavement reconstruction and traffic control during construction.

Awards

Trailblazer Award – 2013 Texas Society of Professional Engineers, South Plains Chapter

Silver Medal Winner – American Council of Engineering Companies Texas, 2013 Engineering Excellence Awards

Project Leadership

At Parkhill, We're Designing and Building for

Your Tomorrow

El Paso Water

- treatment

- El Paso, Texas

Construction Type

Improvements

Project Delivery Method

Design-Build

Project Components

Bridge crane, monorail conveyance system, an outdoor elevated landing area for hoisting equipment, structural steel and foundation for the elevated landing area, installation of an access doorway for the monorail, and removable guard rails around the flocculation basins

Parkhill was tasked with a perplexing problem in the Upper Valley Water Treatment Plant: how to smoothly install a long traveling bridge crane over the operating flocculation basins in a tight building without harming light fixtures and other hardware. Before, operations personnel had to “muscle it out” and cart items down a stairwell that made two 90-degree turns or convey it manually to another building.

Replacing equipment under a pitched roof was difficult. Parkhill provided design, bid and construction phase services to ensure the crane system was suitable for moving equipment weighing up to a half ton outside to a monorail that can lift up to a ton of equipment. With the monorail hoist and platform, workers can lower items over the edge rather than going down several flights of stairs and back up.

Parkhill also analyzed every piece of equipment, including flocculator shafts, motors, gearboxes, and inclined plates, and realized a smaller size of crane and monorail could do the job. This and recommending eliminating a second bridge crane on top of one of the sedimentation basins resulted in saving El Paso Water a significant amount of money.

Project Leadership

At Parkhill, We're Designing and Building for

Your Tomorrow

City of Wheeler

- treatment

- Wheeler, Texas

Project Size

1.0 MGD

Construction Type

Improvements

Project Delivery Method

Design-Bid-Build

Project Components

Hydraulic design, piping, architectural and structural, reverse osmosis treatment process

Parkhill completed Wheeler Reverse Osmosis Water Treatment Plant in Wheeler, Texas, in 2016. The plant uses a reverse osmosis technique that is unique to the Texas Panhandle. With the help of a membrane, the water treatment plant is able to use available groundwater resources and pumps 1 million gallons per day (MGD).

Wheeler had historic problems with high nitrate issues in the groundwater. Parkhill was originally contacted to provide alternatives to the existing groundwater for the city’s potable supply. After evaluation of alternatives, the city selected treatment of the existing groundwater instead of alternate sources. The city was advised to pursue reverse osmosis treatment as it provided treatment for other possible constituents of concern in addition to nitrate.

Pilot studies for reverse osmosis systems were required by the Texas Commission of Environmental Quality (TCEQ) at the time of the project’s inception. Parkhill coordinated the pilot study complete with protocols, manufacturer coordination, testing coordination, and final pilot reporting to TCEQ. The results of the pilot study identified that reverse osmosis rejected over 96 percent of the nitrate present in the groundwater and proved to be an effective treatment alternative.

The plant was initially designed to treat up to 1.0 MGD, but the design facilitates future expansion of up to 2.0 MGD. The project site had new security fencing installed, and the public water filling station from the city hall was relocated to the water treatment plant site. The design of the plant included a new treatment building, a finished water ground storage tank with a capacity of 25,000 gallons, a concentrate tank and discharge, an on-demand raw water sale station, chemical feed systems, plant piping, a new gas chlorination system, and numerous electrical upgrades. A backup generator and power system were also installed to ensure that the city would have a constant source of clean water.

Parkhill oversaw construction of the facility. RPR services were crucial for ensuring the level of quality was as specified. Several major items were rejected, and the Parkhill RPR team worked with the city and the contractor to keep the project moving forward while still being fair to the project documents.

Upon startup of the facility, Parkhill coordinated blend ratios and post-treatment to ensure a smooth transition to reverse osmosis water. Parkhill worked diligently with the city to get all warranties, documentation, and training performed prior to the closeout of the contract. The project was completed in 2016 and is a point of pride for the City of Wheeler.

Awards

- American Council of Engineering Companies Texas Engineering Excellence Gold Medal Winner – Water and Wastewater

- ACEC Engineering Excellence National Recognition Award

Project Leadership

At Parkhill, We're Designing and Building for

Your Tomorrow

Border Environment Cooperation Commission

- treatment

- El Paso, Texas

Project Delivery Method

Study-Report-Planning

Project Components

Feasibility planning

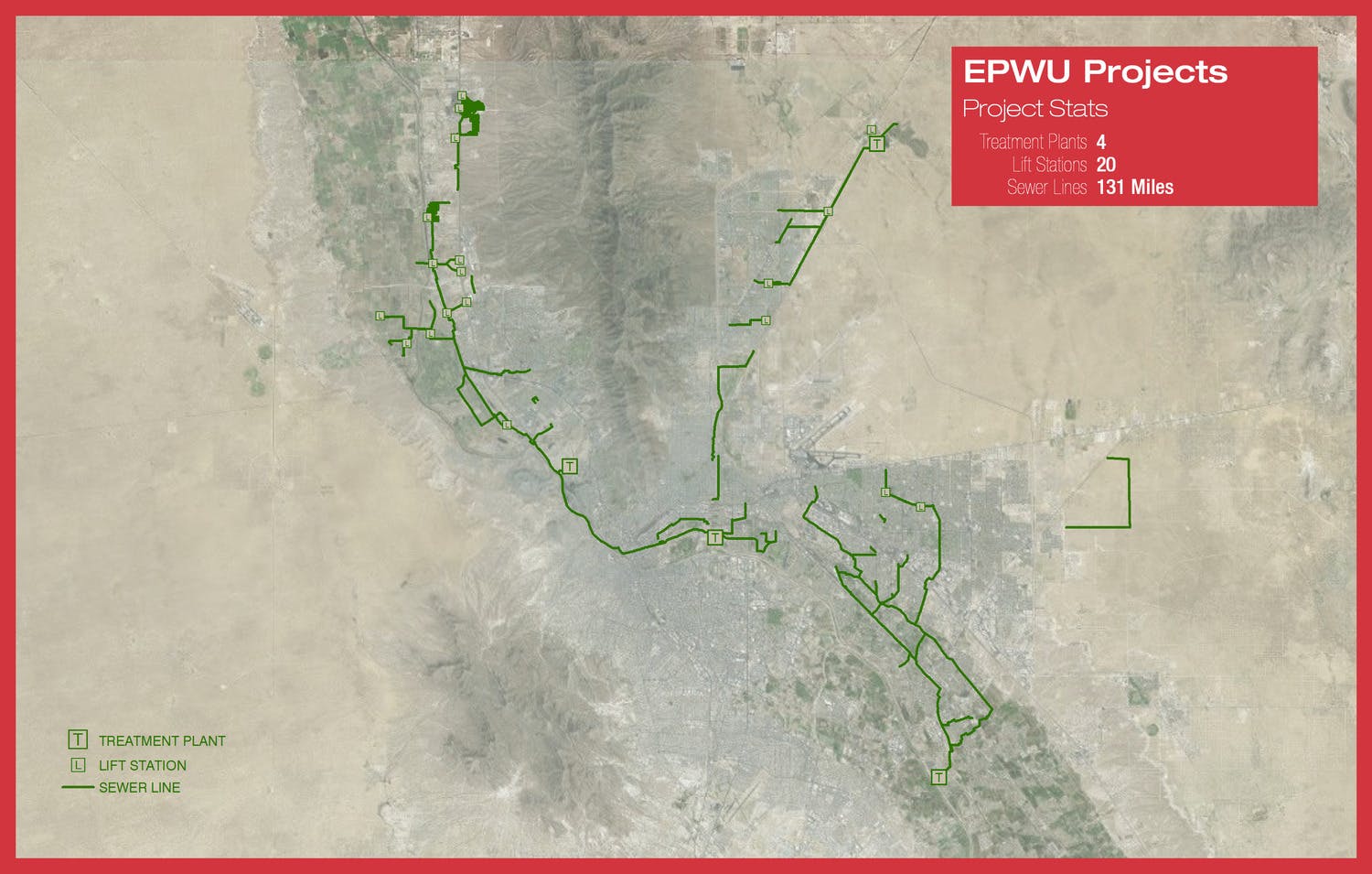

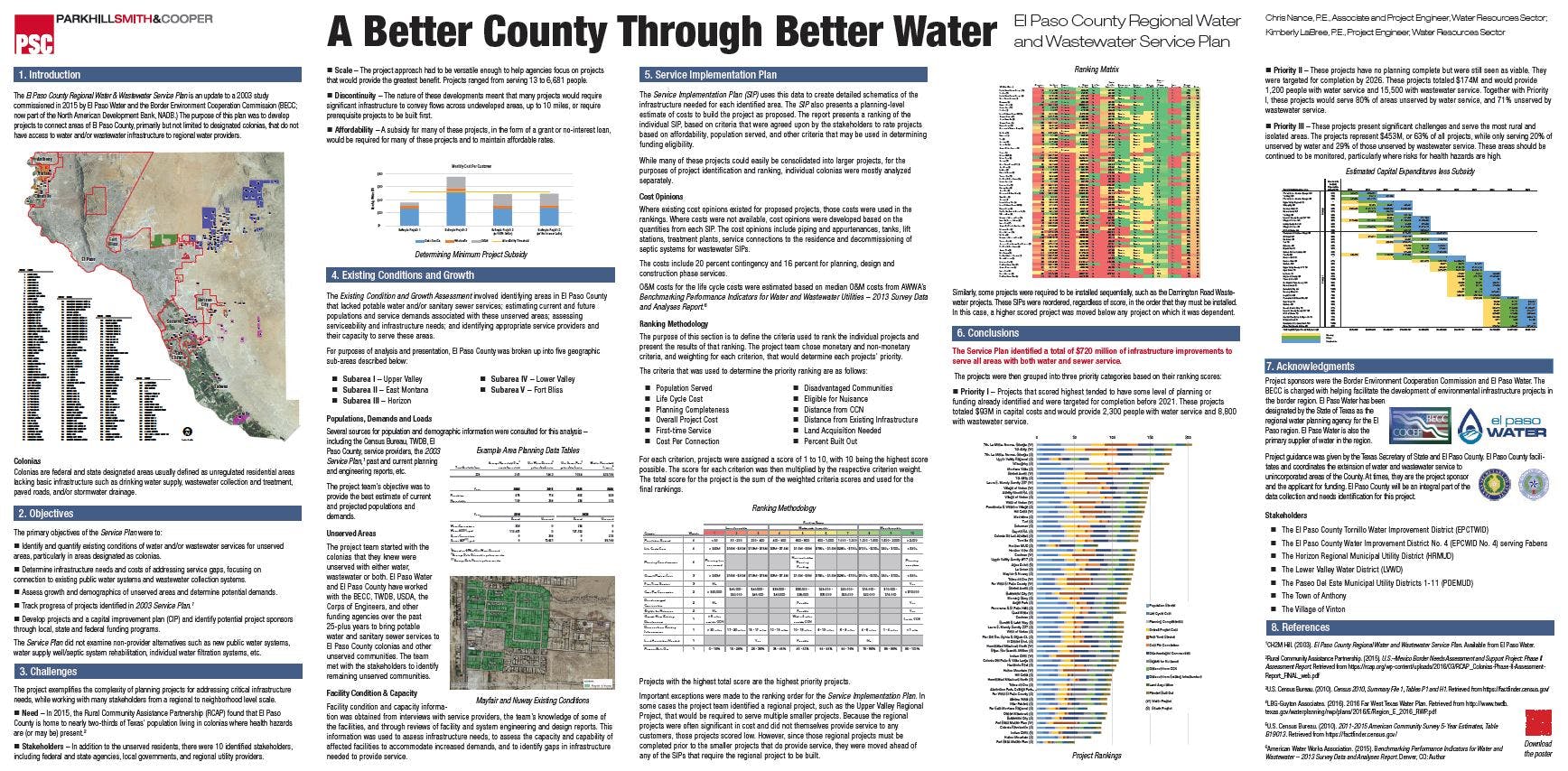

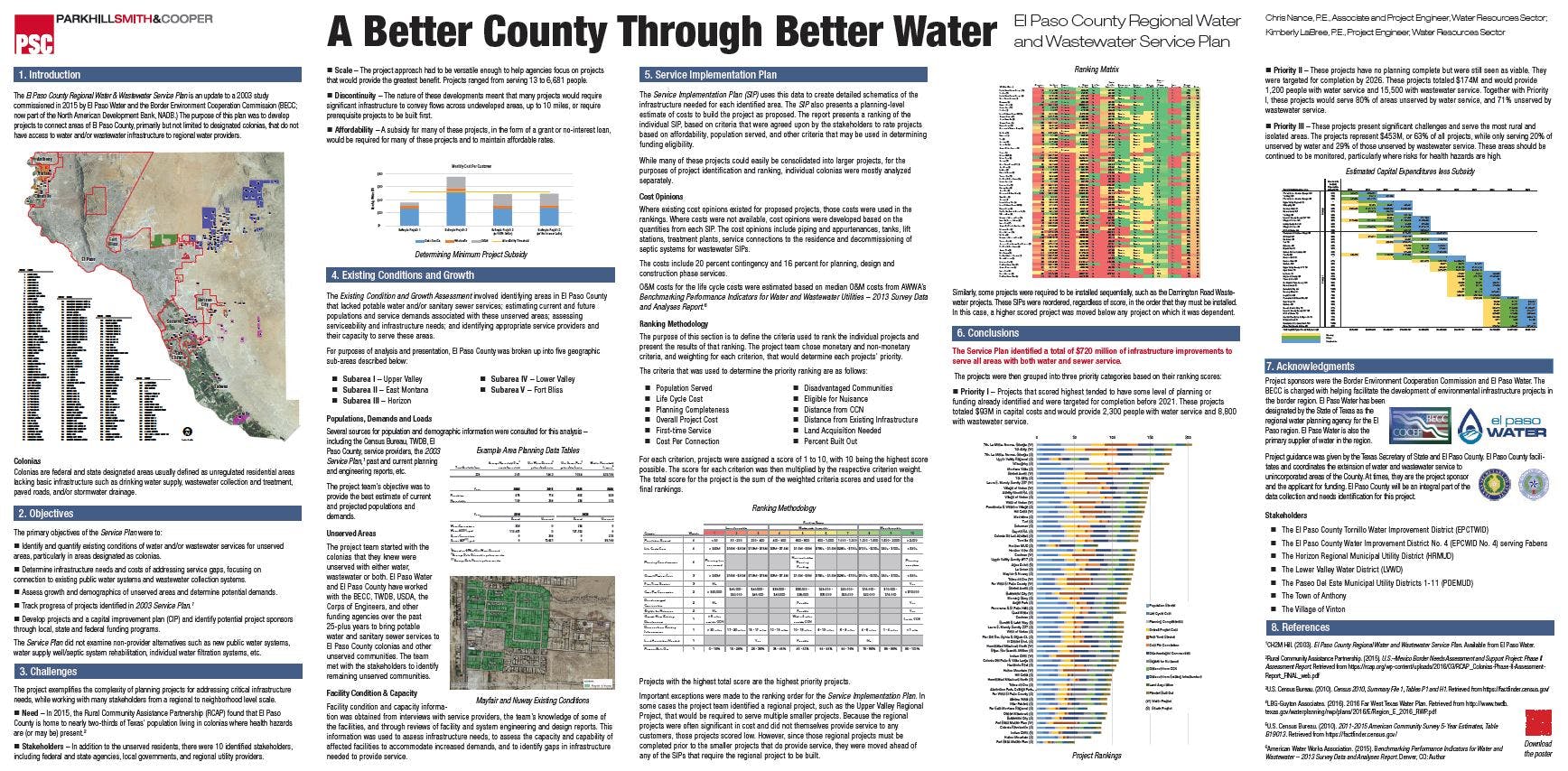

Unique in its complexity and size, the El Paso County Regional Water and Wastewater Service Plan identified a total of $720M in infrastructure needs through 63 individual projects, including 15 water distribution and 48 wastewater collection projects. The plan identified $267M in water and wastewater capital projects over the next ten years.

The service plan centered on identifying and assessing the conditions in colonias within El Paso County that are currently unserved by a centralized water and/or wastewater system. Although colonias make up only 5 percent of the county population, they contain two-thirds of Texans with the highest needs for water and wastewater services. In the service plan, we identified the infrastructure required to provide these areas service from the major water and wastewater systems within the county.

Projects were scored and ranked based on criteria that focused on cost-effectiveness and need. The plan evaluated the costs per customer, including capital, debt service, and ongoing operations and maintenance costs, to determine minimum assistance needed to maintain affordable rates. The plan will serve as a roadmap for area utilities to prioritize and pursue projects that will make the greatest improvements to public health.