El Paso Water

- water resources

- El Paso, Texas

Project Scope

2 miles

Project Delivery Method

CMAR

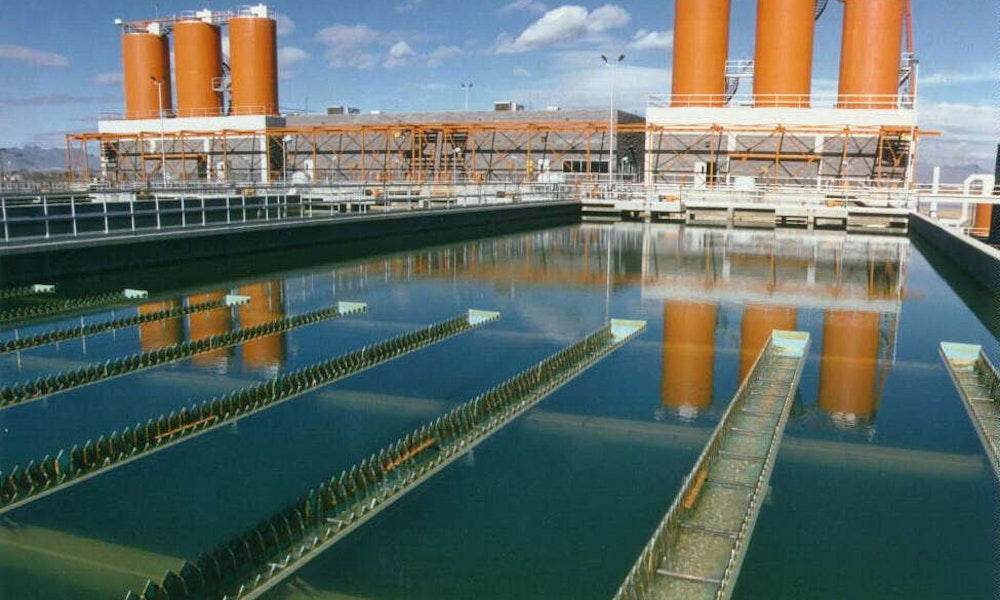

Over the past several years, El Paso Water has seen issues with leaks and breakages in the pipeline along Doniphan Drive, a major traffic route in El Paso’s Upper Valley. The Doniphan Rehabilitation Project was designed to fix almost two miles of 24-inch sewer main on El Paso’s West Side and provided a quality development that would reduce excessive costs.

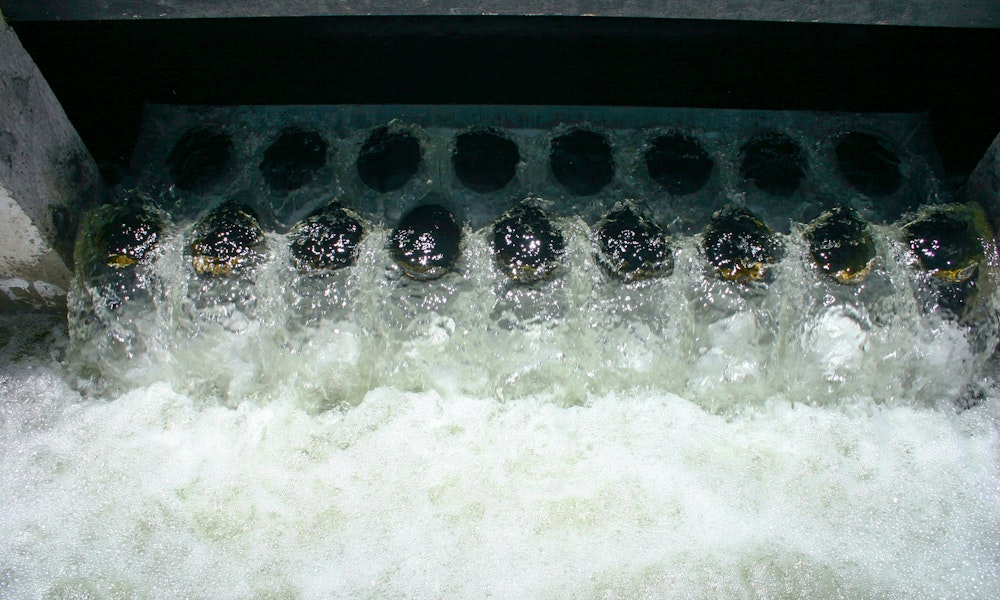

The line lies just outside of the Union Pacific Railroad right of way and just behind the existing curb line of Doniphan Drive. A large portion of it was made of leaky clay pipes, a material that has not been used since before the 1980s because it makes the joints hard to seal. The line was also located within the groundwater table, and since it was in poor condition, increased infiltration into the system and forced El Paso Water to process additional flow.

To solve these issues, the line was segmented into three portions between the intersections of Mesa and Doniphan and Frontera and Doniphan. This line was receiving small amounts of flow from businesses along Doniphan and some residents east of Doniphan.

The middle portion, from Teramar to Coupland, has in the past few years been replacing approximately 3,600 linear feet of the clay pipe with PVC. However, the other two sections of the line still had numerous cracks and voids in the pipe. This led to groundwater infiltration and required El Paso Water to perform the additional treatment of the sewage.

Opencut construction was a method the team considered, but it would have reduced Doniphan, a principal arterial, to one lane in either direction. With average annual daily traffic values ranging between 12,000 and 21,000 vehicles per day, this was not a feasible option. Instead, El Paso Water chose cured-in-place pipe (CIPP). Installing CIPP is like inserting a “sock” into the inside of a bigger pipeline for little to no disruption to traffic.

This was a fast-track project. El Paso Water used the Texas BuyBoard to streamline the negotiation of prices allowing them to bypass the typical bid phase process, which shortened the overall construction time.

The project entailed the evaluation and pressure cleaning of the line in all three sections and the overhauling of 24 utility holes. The contractor lined the first and last portions (equaling about 6,000 feet) with 12-millimeter CIPP. After each segment of CIPP was installed, the line was videotaped by a miniature remote-control robot camera and reviewed for final quality assurance.

This was a high-profile project. Extraordinary care had to be taken due to its location along a busy thoroughfare and adjacent to Country Club Road, where there is also frequent traffic. The rehabilitation has given El Paso Water a quality development that will reduce needless treatment and excessive costs. The project was completed on time and under budget.